![]()

The text, photographs and

drawing below are taken from: 'Notes & Queries: French

Harpsichord Register-Regulation Plates', Galpin Society Journal, 69

(2012).

Figure

1 -

The double-manual harpsichord by Pascal Taskin, Paris, 1769.

Russell

Collection, University of Edinburgh

A by-product of the background research

which I have carried out during the restoration of the splendid

Franco-Flemish

harpsichord is the discovery of a sophisticated and highly-accurate system for

the regulation of the upper-register positions on the 1769 Pascal Taskin

double-manual harpsichord in the Russell Collection at the University of

Edinburgh. The original plate was not

being used on the Taskin instrument at the time I made the discovery and its

function had been replaced by a collection of paper and card shims.

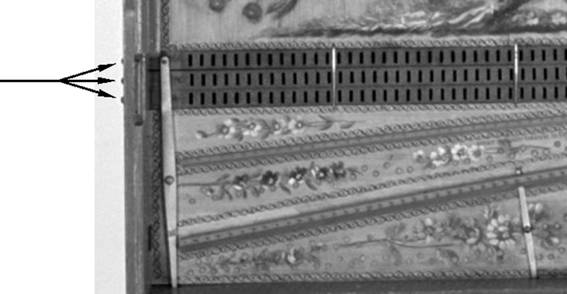

The regulation plate is shown below in

Figure 2.

It consists simply of a beveled iron plate with 3 machine-screw bolts

located in positions opposite the ends of the 3 upper guides. The plate is held and fixed in place with two

wood-screws on the spine side of the instrument.

Figure 2 - ¾-view of the spine register-regulation plate in situ on the instrument. Scale: approx. 1:1.

Double-manual

harpsichord by Pascal Taskin, Paris, 1769

Russell

Collection, University of Edinburgh

Figure below shows a plan view of the register-regulation plate removed from the instrument. Unfortunately 2 of the 3 machine-screw bolts are now missing and the wood screw at the left-hand end of the plate is a replacement 19th-century screw, probably dating from the restoration of the instrument by Tomasini in Paris in 1882. The presence of an original eighteenth-century screw (on the right in Figure 2 above and Figure 3 below), leads me to believe that the plate and the system of regulation it provides is original to the instrument.

Figure 3 - Plan view of the spine registers regulation plate with two wood screws. Scale 1:1.

Double-manual

harpsichord by Pascal Taskin, Paris, 1769

Russell

Collection, University of Edinburgh

The idea of the register-regulation

plate is quite simple. When the

registers are pressed against them and the machine-screw bolts are screwed in

and out, the position of the register in the instrument can be regulated very

accurately. The screw pitch of the one

remaining machine-screw bolt in the plate was measured and found to be very

close to 1mm. Therefore screwing the

machine-screw bolt in by one full revolution (360º) moves the end of the bolt

by 1mm. A half a revolution (180º) moves

it by 0.50mm, a quarter of a revolution (90º) by 0.25mm, etc. Hence a rotation of the machine-screw bolt by

36º moves the end of the bolt by only 0.10mm.

Rotating the screw bolt by less than 36º moves the end of the register

by even less than 0.10mm! Clearly this

is a very accurate method of positioning the register, and is completely

reliable and reproducible: every time

the register is pushed against the end of the machine-screw bolt it returns to

exactly the same position. Therefore the

amount that the quills in the jacks project under the strings is the same each

time the register of jacks is moved against the machine-screw bolt, and the

regulation and voicing of the instrument is maintained with precision and

complete reliability.

Like virtually all French

eighteenth-century double-manual harpsichords that I know, the 1769 Taskin in

the Russell Collection has the registers in the following order (looking at the

registers from above and from the keyboard end of the instrument). The arrows indicate the direction of plucking

of the quills:

← - Rear

lower-manual 8'

← - 4'

sitting on the lower manual

→ - Upper-manual

8' permanently engaged

The two

rear registers both pluck to the left (bass side) and are controlled by

register levers that are attached to the registers and project through the

nameboard with a screw pivot placed in the wrestplank. Using these levers the registers can be moved

from side to side so that that the register of jacks can be engaged and

disengaged by the player. For the two

rear registers, moving the register lever to the right at the player end moves

the register to the left at the register end and engages the jacks for that

register. Doing so therefore pushes the

register against the machine-screw bolt in the register-regulation plate where

its position is determined by the amount the machine-screw bolt projects

through the plate. Therefore the

principle of the use of the register-regulation plate is the same for the two

rear registers (or for the three rear registers if the instrument is endowed

with a peau-de-buffle row of jacks which always plucks the same string

as the main lower-manual 8' row of jacks).

The principle of operation of the near

upper-manual 8' set of jacks which plucks toward the treble side is clearly

different from that of the lower-manual jacks all of which pluck to the left

(bass side). The position of the

register for the upper-manual row of jacks is fixed and always remains

engaged. It cannot be removed and

disengaged, and so it has no register lever associated with it. Since it plucks to the right, the

machine-screw bolt for this register cannot control the engaged position

of the register and the quills as happens with the rear registers. Instead the upper-manual register is equipped

with a small, strong spring hidden inside the treble end of the register. This spring can be seen in

Figure 4

below with the upper-manual register

removed from the instrument and again in

Figure 5 where the register and spring can

be seen in the register gap.

Figure 4 - The treble end of the upper-manual register with the spring.

Double-manual

harpsichord by Pascal Taskin, Paris, 1769

Russell

Collection, University of Edinburgh

This spring acts to push the

register and its jacks towards the bass side of the instrument and against the

end of the corresponding machine-screw bolt in the register-regulation

plate. Therefore the machine-screw bolt

can be used to move the register with its jacks to the left and right in order

to control the amount that the quills project underneath and past the upper-manual

strings. The near upper-manual register

is therefore always held in the same position and can be positioned with the

same precision and reliability as the rear registers.

Figure 5 - The treble ends of the three registers in situ showing the near upper-manual register with its spring.

Double-manual

harpsichord by Pascal Taskin, Paris, 1769

Russell

Collection, University of Edinburgh

The treble ends of all three of the registers in the 1769 Taskin double-manual harpsichord can be seen in Figure 5 above. The register lever plate had been temporarily removed when this photograph was taken, and the spring can be seen expanded to its full extent. Here the screw hole in the 4' register for the 4' register lever can be seen in the middle register (the rear 8' register is operated by a register lever on the bass side of the instrument). When the regulation plate is screwed in position the spring at the treble end of the upper-manual register is compressed leaving about only 1mm of spring exposed and 1mm of space between the end of the upper-manual register and the inside surface of the cheek.

Each of the three machine-screw bolts on the register-regulation plate can therefore be used to position its corresponding register very accurately and reliably so that the regulation of the instrument is always maintained with the same precision and constancy.

It is somewhat surprising that this register plate has not been reproduced by makers of copies of this instrument. The 1769 Taskin double-manual harpsichord is perhaps the most copied French double-manual harpsichord in the world, but I know of no one who has made a register-regulation plate for their copy. The drawing - TD1[1] that I made of the instrument in 1974 shows the register-regulation plate clearly and with 3 machine-screw bolts. It is clear from a photograph taken by the author in 1979[2] when the instrument was being restored by John Barnes (see Figure 6 below), that there were the original 3 machine-screw bolts present at that time.

Figure 6 - Photograph of part of the spine, the bass ends of the registers and the bass end of the wrestplank with the nuts and plugged tuning-pin holes.

Double-manual

harpsichord by Pascal Taskin, Paris, 1769

Russell

Collection, University of Edinburgh

The photograph shown in Figure 6 was taken during the restoration by John Barnes of the instrument in 1979. Before 1979 the instrument had large modern zither-pins instead of traditional flat-sided tuning pins as made in the historical period. Barnes removed the zither pins, plugged the holes in the wrestplank with hardwood plugs and then drilled these out to take new reproduction tuning pins of a traditional design and smaller diameter as was used in other instruments by Taskin. The photograph shows that the tuning-pin holes have been plugged with hardwood plugs, but these have not yet been drilled out for the new reproduction tuning pins. This fact therefore dates the photograph precisely to the year of the restoration of the instrument which was 1979. The important feature of this photograph is that it shows the heads of the 3 machine-screw bolts of the register-regulation plate at the spine side opposite the bass ends of the registers. This means that in 1979 all three of the machine-screw bolts existed and were being used. As mentioned above there now remains only one of the machine-screw bolts indicating that in the intervening period two of the three bolts have gone missing at the hands of the restoration staff at the Russell Collection. Hopefully new machine-screw bolts will be made for the register-regulation plate with the same screw pitch as the original remaining bolt so that the original function of the plate can be re-instated.

As mentioned above I discovered the original register-regulation plate and its original function in the process of the restoration of a stunning Franco-Flemish double-manual harpsichord that I have been restoring in the past years. Naturally for an instrument of its significance and importance, I wanted to utilise this system for regulating the registers in the restoration of this instrument. The Franco-Flemish harpsichord has the usual French disposition with a French keyboard coupler, coupler dogs, and four registers including a row of peau de buffle jacks at the rear plucking the same string as the main lower-manual 8' set of strings.

In this case, therefore, the plate had

to have 4 machine-screw bolt regulators including one for the rear peau de

buffle register. The dimensions of

the register-regulation plate and the

positions of the holes for the retaining wood screws and those of the

regulating screw bolts was adapted to suit the Franco-Flemish instrument. The result of the new design is shown in the

drawing of

Figure below. Here the dimensions of the machine-screw

regulation bolts, the thickness, width and beveling of the plate, the upper-manual

register spring and the original screw are exactly the same as those of the

1769 Taskin double-manual harpsichord in the Russell Collection. The machine-screw bolts have a length of

8.2mm of threaded lower section. The

thickness of the register plate itself is 5.2mm so that the machine-screw bolts

can project a maximum of 3.0mm towards the bass ends of the registers. This corresponds to the maximum amount that

the ends of the registers can be positioned away from the outside spine surface

of the instrument. In practice it is

relatively easy to cut the length of the registers so that the gap between the

end of the register and the end of the machine-screw bolt is about 1mm or less. Therefore this 3.0mm of possible movement is

more than sufficient in practice given the small amount of sideways movement

that the jacks can have given the small amount of space available between the 3

sets of strings. The position of the holes for the retaining wood screws was

measured out to be the same as the existing wood-screw holes beside the

register gap-cut-out (perhaps for a similar regulation plate) on the spine side of the Franco-Flemish harpsichord being

restored. Using these dimensions a new

4-machine-screw bolt register plate was made.

Note to scale!

Figure 7 - A drawing of the spine register-regulation plate made for the c.1617/1750 Franco-Flemish harpsichord which has 4 registers, unlike the 1769 Pascal Taskin harpsichord in the Russell Collection which only has 3.

A drawing made using AutoCAD is available by clicking here

and another in Word 2000 by clicking here

and another as a .TIF file by clicking here.

The new register-regulation plate, made

for the Franco-Flemish harpsichord, is shown below in Figure 8.

The wood screws used to hold the plate in place are 19th-century

narrow-slot screws. Otherwise the plate

and the regulation bolts are all new.

Figure 8 - A photograph of the finished spine register-regulation plate made using the drawing inFigure 7 above. In the background of the register-regulation plate is the luxurious vernis-martin decoration on a gold background. Scale 1:1.

Because of severe damage to the originals suffered in the past, new registers were made for the Franco-Flemish instrument in the course of its present restoration. The new upper-manual register, of course, needed a small strong spring inset into its treble end like that shown in the photograph of Figure 4 above and drawn in Figure 7. Springs with dimensions and properties very similar to this spring are available commercially from a number of different suppliers at a nominal cost. One such supplier is Associated Spring SPEC, European Headquarters, Unit 4 Grosvenor Business Centre, Vale Park, Evesham, Worcs. WR11 1GS, Tel: +44 (0)1386 443366, E-mail: sales@assocspring.co.uk. The product code of the spring that I ordered and used in my restoration is C02400400620M. This new spring is 6.10mm in diameter and uses steel music wire of diameter 1.02mm. The total length of the spring is 15.75mm, and this compresses to a length of 11.15mm. At this length the compression force is 53.15Newtons (= about 5kg wt). The hole for the spring in the treble end of the upper-manual register was drilled to a depth regulated so that only about 3mm of the spring projected when the register is out of the instrument, and 1mm when it is in place in the instrument. This means that the length of the spring is compressed to a length of 15.75mm - 2mm = 13.75mm in use in the instrument. Using Hooke’s law for springs this means that the force produced in the instrument by the spring is about 23 Newtons, equivalent to a force of about 2.4 kg wt.

The register plate and spring are presently installed, functioning and in use in the Franco-Flemish harpsichord. The system works extremely well. The regulating machine-screw bolts control the position of the registers - and therefore the position of the quills relative to the strings - very accurately with both precision and reliability. I can recommend the system highly and find it simple and easy to operate and control.

-

Grant O’Brien, Edinburgh, 2015

-

all photographs, except for Photo 1, were taken with permission and are by the author