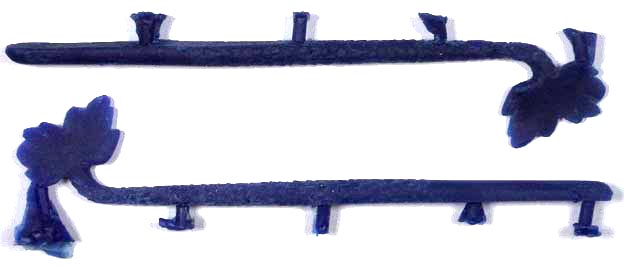

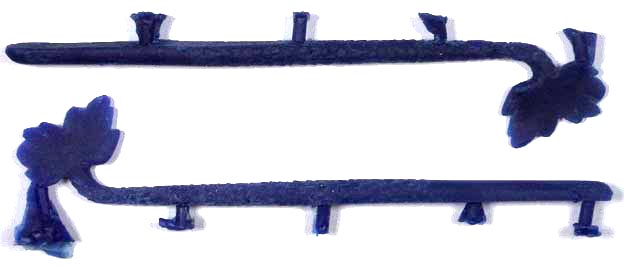

The first-stage wax mouldings that were made directly from the extended wooden model. The spigots left from the casting process were cut off and one moulding was made shorter than the other so that the final lever would reach only to the near register. A recess was made at the end away from the tail in order that the lever could pass over the wrestplank moulding and the slightly-raised registers. The wax mouldings were then heated slightly using only body heat and bent asymmetrically to serve as the left- and right-hand levers and to give them a more rhythmical, 'natural' appearance like that of a real mermaid! Wax pins were added to the underside of the distal end of the levers to form spigots which would eventually engage in the registers. This then gave two wax models, one for the left-hand and one for the right-hand side of the instrument, to engage the jacks plucking the long and the short 8' strings respectively.

Go back to the main page of this section